|

PAINT AND

POWDER CASE STUDY:

SATELLITE AMPLIFIER MANUFACTURING

Infrared/Convection

Combination Oven conserves floor space and increases line speed for

satellite amplifier manufacturer

Background

The customer was originally using a batch oven to cure the powder on the

satellite amplifiers. This process had several drawbacks; slow

production, poor coating consistency, and inflexible oven design.

After time, it was necessary

to upgrade the oven to achieve higher production rates. Several optional

oven designs were reviewed; larger batch oven, continuous gas convention

oven, continuous medium wave electric infrared oven.

After careful consideration,

it was decided that a larger batch oven could obtain the desired

production, but had too many other drawbacks (as noted above). The

continuous convention oven required more floor space than was available

in order to obtain the desired production rate.

The electric infrared oven

achieved all of the goals for a new curing oven:

- faster

production

- minimal

floor space

- reduced

maintenance requirements

- low

energy consumption

- reasonable

capital expenditure

- flexibility

for faster production rates in the future, accomplished by sectional

oven design

ADVANTAGES

OF USING IR FOR THIS APPLICATION:

Floor

Space Floor

Space

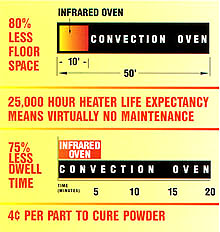

It was estimated that a

40'-50' long convection oven would have been required for this

application. The infrared oven length is 10'. Either oven would require

a 15' area for loading and unloading the parts.

Maintenance

A gas convection oven

would require preventative maintenance several times a year. The

infrared oven has been installed for 2.5 years with no requirement for

maintenance to date. With a typical life expectancy of 25,000 hrs for

solar products panel heaters, the customer will be operating for a long

time without any maintenance problems.

Line Speed

A gas convection oven

would have required a 20 minute dwell time. The original infrared oven

design was based on line speed of 1 fpm and a dwell time of 10 minutes.

In actual operation the conveyor speed is 1.5 fmp with an oven dwell

time of 5-7 minutes.

Energy

Consumption

The input power rating is often viewed as the actual power usage for an

electric infrared oven. In this case, the oven had 70kw of electric

infrared installed. But, in actual operation, the energy usage is less

than 30 kw. The energy cost calculation is 30 kw x 12 cent per kw*hr

=3.60 per hour of operation. At 90 parts per hour, that equates to 4

cent per part. The energy consumption for paint and powder applications

typically accounts for less than 1% of the product selling price. Our

guess is that 4 cent is well below that 1% margin. The best part of

Solar Products panel heaters is that there are no external reflectors.

External reflectors only get dirty over time, which reduces the heater

efficiency. Solar products heaters maintain a consistently high radiant

efficiency (80%) over time.

|

Specifications |

Details |

|

|

Part Description |

Aluminum or magnesium

cast parts variable wall thickness |

|

| Part type |

Satellite dish

amplifiers for the communications industry |

|

| Coating |

Polyester powder |

|

| Coating application |

Manual electrostatic

spray |

|

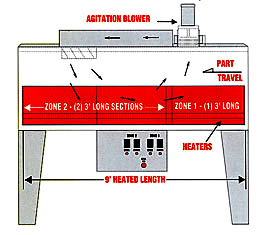

| Length of oven |

10' long oven |

|

| Zones per oven |

2 zones - 9' heated

length for both zones |

|

Zone 1

Zone 2 |

3' long section

operating at 900o F

(2) 3' long sections operating at 875o F |

|

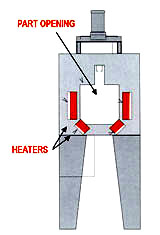

| Oven type |

Infrared with air

assist |

|

|

Heater type |

Solar Products

F-Series panel heaters |

|

| Input power |

70kw for the heaters |

|

| Actual power usage |

Less than 30kw |

|

| Conveyor type |

Overhead monorail |

|

| Conveyor speed |

1.5 feet per minute |

|

| Weight of part |

5 lbs max |

|

| Production rate |

90 parts per hour |

|

| Gel and cure time

(dwell time) |

5 - 7 minutes |

|

|